Calculator

Brief user guide - METGROW+ tool

How we do it:

Toolbox

The ICT-Toolbox produced gathering all the information from the decision support framework is the main METGROW+ project end-product. As reflected in the Grant Agreement, "a flexible new metallurgical systems toolbox that allows finding the best combination of processes for a selected low-grade resource will be produced".

Definition of the functionalities

Considering the definition in the grant agreement, the developed tool should be able to provide alternative processes for each raw material and these will be selected depending on the chosen criteria. Thus, several pathways for the same raw material have been assessed through the application of LCA, TEA and RA methodologies. The information produced in the assessment is treated and stored in a database, which feeds the web tool.

The web tool has been produced and hosted in the domain idener.es. The implementation of the first version of the METGROW+ toolbox has been done using ASP.net core, latest open source technology from Microsoft that ensures portability on different platforms. It uses Microsoft SQL standard version as databases. The whole system has been dockerized for ensuring fast deployment and easy maintenance of the solution.

The toolbox addressed the inclusion of new materials and processes and, therefore, the wide application of the tool in metallurgical processes. To that end, the selection of a specific resource would be replaced by the selection of material characteristics such as the content in key metals.

Functional requirements

The end-user would be able to select (1) the material among those indicated, (2) EU member state (3) the weight of each of the evaluation criteria. These criteria would be related to (1) environment assessment (LCA), (2) techno-economic (TEA) and (3) risk assessment (RA)) and would be calculated according to the methodology set in the multicriteria analysis step. The produced output would be the information about the process that best fits the selected criteria among those assessed for materials with similar characteristics

Multicriteria Analysis

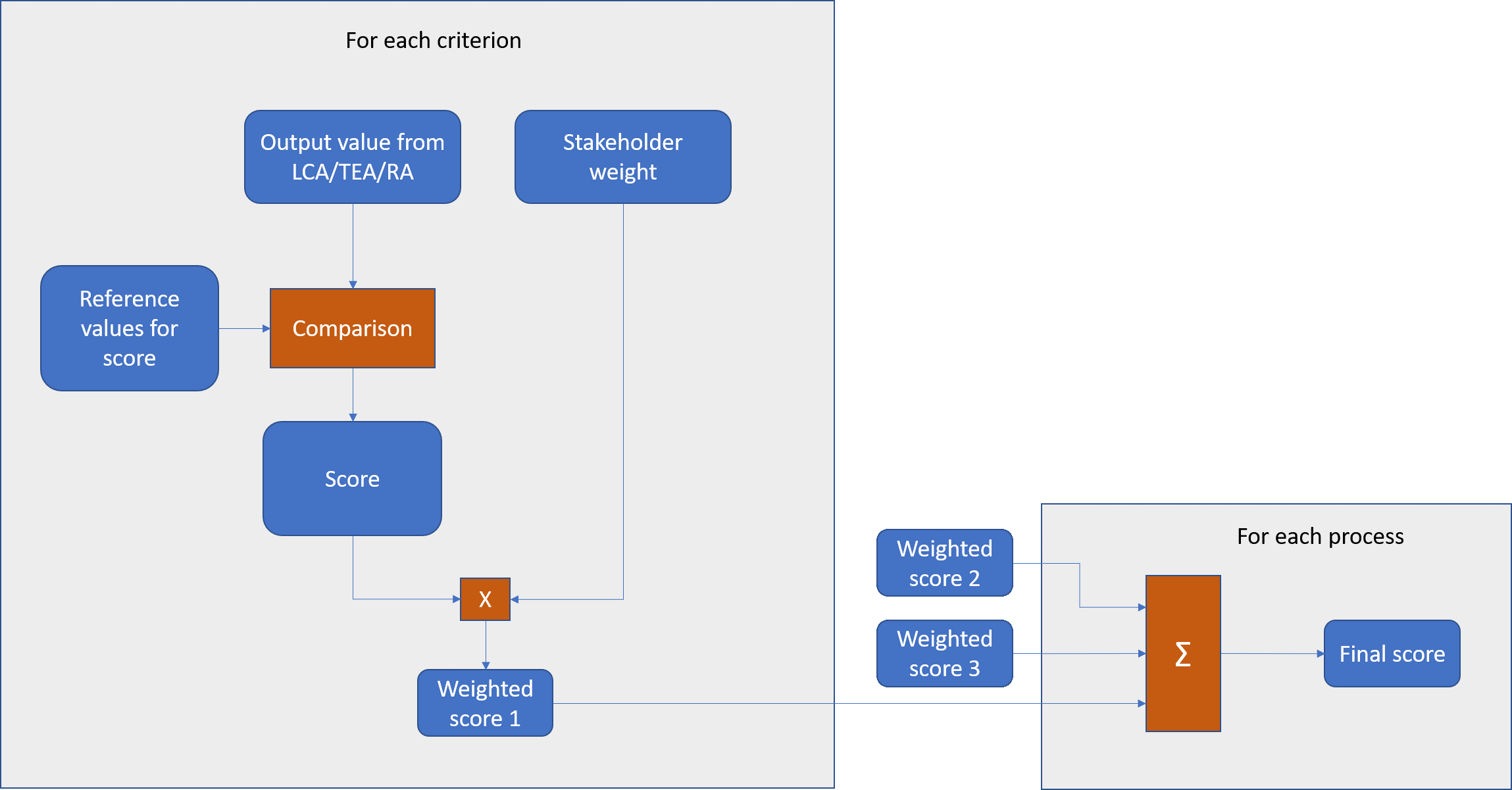

The general methodology follows the following procedure:

- Values for each criterion for each process, which are outputs from LCA, TEA and other sources, are compared to a reference value and given a score.

- A weighting procedure is performed with local and regional stakeholders where each criterion are given weights (0-100 percent) depending on their relative importance (with the sum of all weights should equal 100).

- The score of each criterion for each process is multiplied with the weight chosen for that criterion, which gives a weighted score.

- The sum of all weighted scores for each process gives the final score for that process, which is the value that is used to compare different processes.

This methodology is presented graphically in the following figure:

| Score | Meaning | |||

| Environmental aspects | Hazards | Economic aspects | Legislation/Acceptance | |

| ++ | Large avoided impacts | No hazards idenfied | Very profitable | Very positive |

| + | Intermediate avoided impacts | No severe or high concern hazards, less than 3 minor hazards | Profitable | Positive |

| 0 | No net impacts (avoided or additional) | No high concern hazards, less than 2 severe hazards, and/or more than 3 minor hazards | Not profitable | No impact |

| - | Intermediate additional impacts | 1 high concern hazard, and/or more than 2 severe hazards | Unfavourable economically | Negative |

| -- | Large additional impacts | More than 1 high concern hazard | Very unfavourable economically | Very negative |

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 690088.

Brief user guide - METGROW+ tool

How to use the tool:

Open the application

It is possible to access the METGROW+ toolbox by clicking on the following link:

http://app.metgrowplus.eu/Calculator

Get access to the premium profile

The premium profile grants access to the quantitative (not only qualitative) information about the best process to treat the selected waste. All the members of the METGROW+ consortium will enjoy a premium profile. To access to the premium profile, please, click in the upon menu in the option “Calculator-Paid”.

Introduce the information about the target waste

Once selected the target waste, its characteristics will be introduced in the application as follows:

1. Select the Material Type

2. Select the Material

3. Select the content in metals of interest (Co, Zn, Pb, etc.)

4. Select the region/country to be considered for the assessment of the process (EU28, Spain, etc.)

5. Finally, select the weight (Neutral, Relevant or Highly relevant) of the different criteria in the assessment

Run the calculation

Please, just click on Calculate button

Management of the output information

Whether a material with characteristics similar to those introduced is found in the database, the application returns a scheme of the best process(es) for its treatment, according to the performed assessment. Besides, the information result of the assessment is shown. The diagram of the process can be exported as a pdf.

Error messages

No pathways with similar contents found for the given material and country

There are not similar materials in the database or their assessment has not been performed for the selected region

Contact:

Metgrow+ contact person: Päivi Kinnunen (email: Paivi.Kinnunen@vtt.fi)

For technical issues with the calculator app: info@idener.es

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 690088.

Description of materials

Greek laterites

Low grade iron-nickel ores from Greek deposits. The nickel content ranges from 0.4 to 1.2%, while the iron content ranges from 20% to 50%. Other elements present in significant amounts are silicon, magnesium, calcium, aluminium and chromium while some cobalt is also present. The ore is mainly composed of goethite, hematite, nickel-bearing chlorite, illite, quartz, calcite and chromite.

Polish laterites

Low grade nickel laterite type ore. The nickel content ranges from 0.3% to 1.3% (and more), while Fe2O3 content ranges from 10% to 27%. Other elements present in significant amounts are SiO2, Al2O3, MgO, Cr2O3, TiO2, Co. The ore is mainly composed of weathered serpentinite consisted mainly of magnesium silicates and quartz with iron oxides.

Jarosite

Iron-rich jarosite sludge produced during the hydrometallurgical production of zinc. The sludge has a high water (28%) content and contains mainly jarosite (a mineral of iron sulphate), elemental sulphur, gypsum, silicates and metallic sulphides (mainly iron, zinc and lead). The particle size is very fine (d50 = 3 μm).

Goethite

Iron-rich goethite sludge produced during the hydrometallurgical production of zinc. Goethite sludge is mainly composed of calcium sulphate, iron oxides and zinc oxides.

Landfilled Cr-rich sludges

Chromium- and nickel-rich sludge generated during the neutralisation of wastewater from stainless steel surface treatment with Ca(OH)2. The sludge has a high-water content (47%) and contains mainly gypsum, calcite and magnetite. Chromium is present as chromium sulphate hydrate and chromium oxide, while nickel is mainly incorporated in the spinel-structured trevorite.

Landfilled Zn-rich sludge

Zn-rich sludges generated during the stabilization-inerting process of hazardous wastes and dehydrated through a filter-press. The sludge is mainly composed of zinc, iron and calcium hydroxides, in the 15% to 25% range each, with certain amounts of calcium carbonates and silicates. Water and organic matter contents represent the 60% and 25% of the dry weight, respectively.

Fayalitic slags

Iron- and zinc-rich slags produced from various metallurgical industries. Other elements present in significant amounts are silicon, aluminium, copper and lead. The slag contains mainly iron silicate (fayalite), other silicates, iron oxide and silica.